When are Spiral Rebar Benders used?

When it comes to civil projects that are huge in scale like bridge construction, subway work and other land base filling projects, not only are electric rebar cutters and rebar benders used, but a spiral bender is also essential as well. Spirally bent deformed bars (rebars) will be reinforced with the help with the rebars spirally bent using a spiral bender.

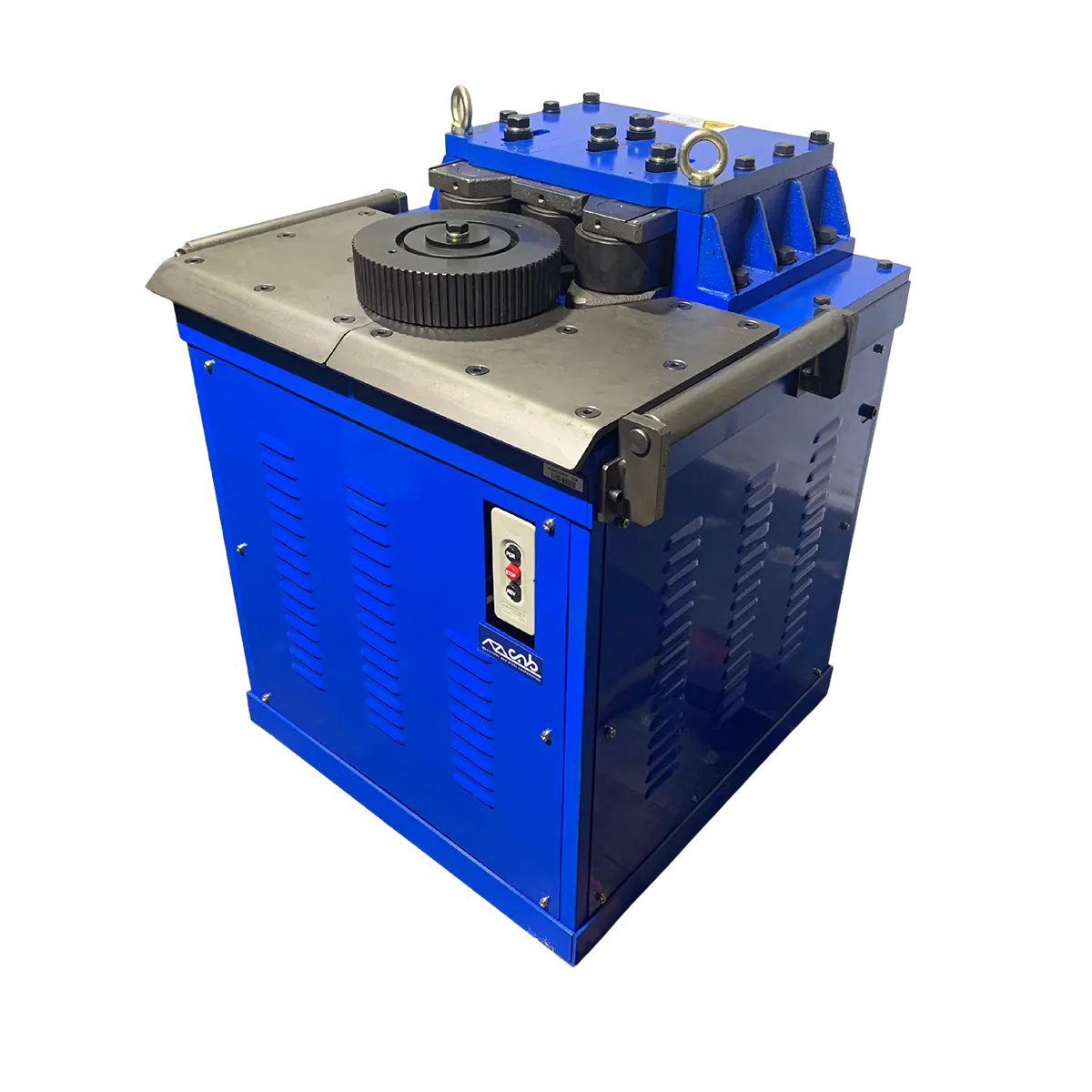

A spiral bender is used to accurately spirally bend the rebars into the shape that is required in the construction project site. As precision is required in spirally bending rebars, we highly recommend you to equip yourselves with a machine that is not only safe to operate, but is also accurate and precise when bending. The TYR-HD32A spiral rebar bender has been carefully designed for the optimal spiral bending of rebars with ease. The electric spiral rebar bender is simple and easy to use as it is operated with simple buttons that the machine operator can easily navigate and use.

The machine operator simply has to turn the on button on to activate the spiral rebar bender. Once the on button has been pressed, the rollers will start rotating. The machine operator will then simply have to properly align the rebar of choice and guide the rebar as it is inserted in between the rollers for the spiral bending. The machine operator will have to be mindful of the rollers and will have to carefully observe the rebars as it is being spirally being bent to avoid any unwanted injuries. The spiral bar bender has been designed for the comfort and safety of its valued operators so the machine operators simply have to be aware and sharp while operating the machine.

The spiral bar bender is equipped with a 5 horse power motor that gives the machine a powerful bending capability. The machine’s powerful bending performance can spirally bend up to 32mm. It will only take 12 seconds to bend a 32mm to 360°. The machine can efficiently bend rebars in the construction site as it is a heavy duty machine built to withstand hard work.

Even though the machine is a heavy duty machine, it is extremely easy and simple to use. The spiral rebar bending machine was designed with the highest quality parts with an extremely simple machine operation process. CNB Machinery and Steel Corporation adhered to the feedback and comments of the machine operator’s experience and continuously makes improvements in the machine and services.

Although the machine is built with high quality parts, improper handling of the machine will lead to machine damage and malfunction. The interior electric motor must not be exposed to rain as this will cause the motor to be damaged which will halt the machine from working. This in return will cause delay in the production of spirally bent rebars. Moreover, this may also injure the machine operator in the process. CNB Machinery and Steel Corporation greatly values the safety of the machine operators and thus we highly recommend the machine operators to follow the instructions found in the machine manual as well as the demo of machines by our technicians upon delivery.

If you are interested in the machine and would like to consult with one of our sales team, feel free to contact our sales representatives through the following numbers. If reaching via telephone, kindly call us through (02) 8824-6386 or (02) 8824-6391. If reaching via mobile phone, kindly call us through 09178837792 or 09178837793. If you would like to email us, simply send us an email at [email protected] for immediate assistance. You can also choose to inquire to our Facebook Page. You may also fill up the form here to receive a quotation from our sales team. We hope to hear from you soon.