High Quality Bar Benders, Bar Cutters and Truck Mounted Mobile Cranes Manufactured in South Korea Distributed in the Philippines

Proudly manufactured and assembled in South Korea, CNB Machinery and Steel Corporation is privileged as the exclusive distributor of TAEYEON B&C electric bar benders and bar cutters here in the Philippines for over a decade. We also supply truck mounted mobile cranes that are manufactured from South Korea here in the Philippines.

We offer a wide array of rebar fabricating products ranging from 10 to 42mm bar bender and bar cutters. We offer unrivaled after sales service to our valued clients as our warehouse is always stocked with brand new machines shipped from South Korea, along with the complete spare parts for the bar bender and bar cutters. We can guarantee that trusting us and investing in our machines just as the leading contractors and rebar fabricators of the Philippines did will be your best decision when it comes to your bar bending and bar cutting machine requirements. Our mobile cranes are one of a kind in the Philippine market as they are compact yet extremely durable. They are also exempted from the truck bans as they are less than 7.5 feet when folded and covered.

Filter

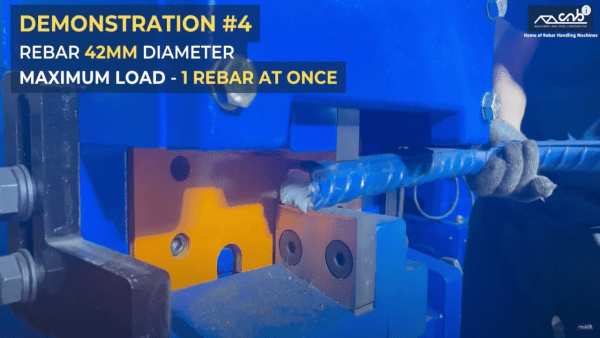

Our powerful and precise bar cutting machines in action!

All the models of our rebar cutters are available in our warehouse. Moreover, we are able to immediately assist our clients with the purchasing of spare parts and machine repair as we have the complete spare parts (that are fast to moderately moving) in our warehouse, along with our roster of highly experienced technicians. We can guarantee that our rebar cutting machines will make a difference in the rebar fabrication experience of your project.

Our hydraulic bar cutter TYC-NHD25 can cut 10mm to 25mm deformed bars.

Our rebar cutting machine that can cut 10-32mm perfect for general constructions.

Our TYC-HD42A is our flagship bar cutter that can cut from 10-42mm rebars.

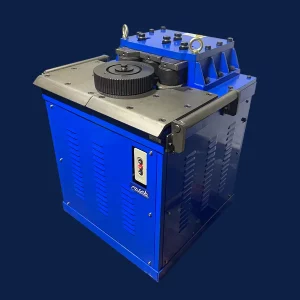

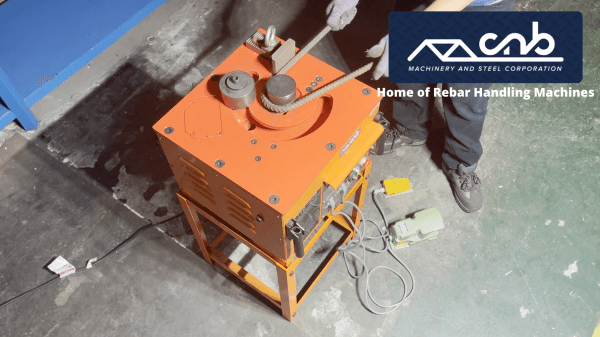

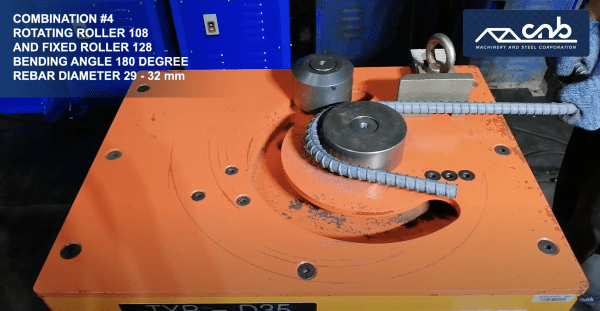

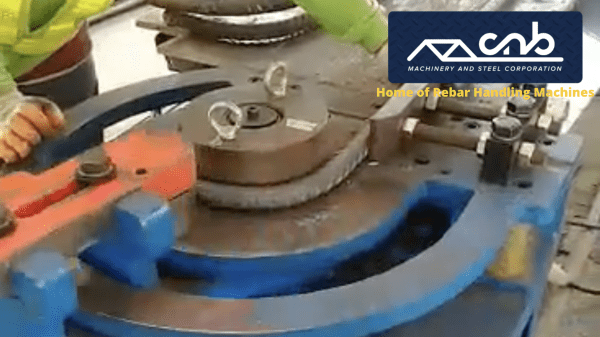

Our accurate and durable bar bending machines in action!

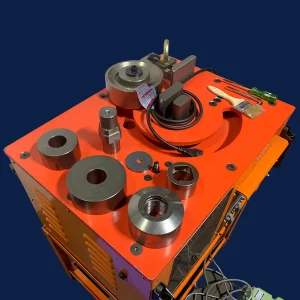

All the models of our rebar benders are available in our warehouse. Moreover, we are able to immediately assist our clients with the purchasing of spare parts and machine repair as we have the complete spare parts (that are fast to moderately moving) in our warehouse, along with our roster of highly experienced technicians. We can guarantee that our rebar bending machines will make a difference in the rebar fabrication experience of your project.

Our TYB-D26 is the portable bar bending machine that is perfect for 10-25mm rebars and quick rebar stirrups.

The TYC-D35 is our general bar bender that can bend from 10-32mm rebars loved by contractors.

It is our heavy duty bar bender that can bend from 10-36mm and can be used to fabricate rebars for big infrastructures.

It is our flagship rebar bender model that can bend from 10-42mm rebars, perfect for civil projects.

FAQs about our bar bender and bar cutters

1. What are your single phased bar bender and bar cutters?

Answer: Our single phased bar benders are our TYB-D26 (25mm capacity) and our TYB-D35 (32mm capacity). Our single phased bar cutters are our TYC-NHD25 (25mm capacity) and our TYC-D35 (32mm capacity).

2. What are your three-phased bar bender and bar cutters?

Our three phased bar bender models are our TYB-HD42A (36mm capacity) and our TYB-HD42D (42mm capacity). Our three phased bar cutter models is our TYC-HD42A (42mm capacity). Our spiral bender TYR-HD32A (32mm capacity) is also three phased.

3. Are your single phased bar benders or bar cutters convertible to three phase?

The only single phase machine we can convert to three phase is our TYC-D35 cutter (32mm capacity). We do not recommend our clients to convert their other single phase machines to three phase. We also do not recommend our clients to convert their three phased machines to single phase as the risk of electrical damage may occur.

4. What are the rebar bender models you would recommend for stirrups?

All 4 of our machines have been designed to bend rebars with great precision, making them great rebar benders for stirrups. The question can be answered depending on the specific requirements that the project has. For quick stirrups for rebars, we highly recommend our TYB-D26 and TYB-D35 models as they would bend smaller diameter rebars compared to our heavy duty models. Although they bend less number of rebars compared to the heavy duty models, the TYB-D26 and TYB-D35 can quickly make stirrups. On the other hand, our TYB-HD42A and TYB-HD42D can bend rebars with thicker diameters and can bend more number of rebars at once. Because it bends more rebars at once, its speed will be a bit slower than the smaller models. At the end of the day, it depends on the requirements of our clients.

5. Do you provide machine repair service for all your rebar bender and rebar cutter models?

Yes. We know that rebar production in a construction site is very important. Thus, when a rebar bender or rebar cutter breaks down, it will cause a huge delay in the overall project. This is why we prioritize our after sales service. We have a roster of highly skilled technicians who can repair your rebar bender and rebar cutters either in your construction site or in our warehouse. The decision is made by our technician on whether or not the machine is repairable in your construction site. If the bar bender or bar cutter needs an extensive repair, the machine will have to be pulled out from your construction site and repaired in our warehouse. For more details, please do not hesitate to contact us by filling out this form or simply by calling us at 09178837792 or 09178837793 for mobile calls and (02) 8824-6386 or (02) 8824-6391 for landline calls. You may also email us at [email protected] as well.

6. What is the maximum capacity of your truck mounted mobile cranes?

Our truck mounted mobile crane's maximum capacity is 1,000kg (1 ton). However, the capacity is decreased as the length of the cranes are increased. The first level of the mobile crane at 1 meter (1016mm) has a maximum capacity of 1,000kg (1 ton). The second level of the mobile crane at 1.6 meters (1776mm) has a maximum capacity of 850kg. The third level of the crane at 2.3 meters (2337mm) has a maximum capacity of 500kg.

You may consult with our sales and after sales team for other questions and concerns using the contact details listed above.