Description

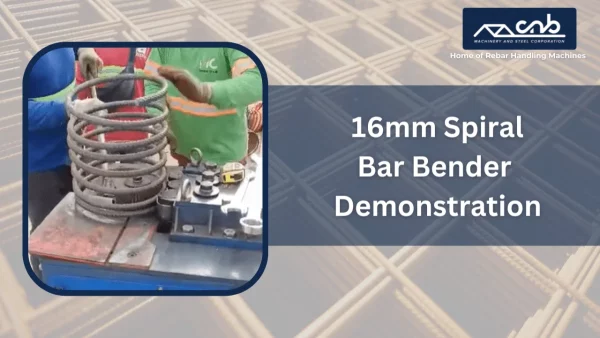

About our 16mm Electric Spiral Bar Bender

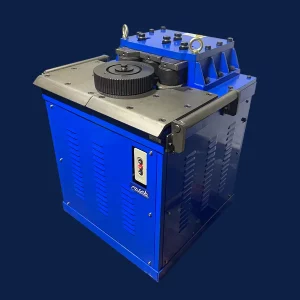

- The TYR-HD25B electric spiral bar bender has been designed in order to provide its machine operators with a better rebar bending experience. The heavy duty rebar bender has a dual adjustable device that allows the bar bender to bend rebars in 2 different angles that can tremendously save work time and increase the production of rebars. The electric spiral bar bender has been designed perfectly for civil construction projects that require a variety of rebar bending work like bridge construction, subway work, and also for land base pilling work.

- The TYR-HD25B spiral bar bender has been carefully designed for the optimal spiral bending of rebars with ease. The electric spiral bar bender is simple and easy to use as it is operated with simple buttons that the machine operator can easily navigate and use.

- The machine operator simply has to turn the on button on to activate the spiral rebar bender. Once the on button has been pressed, the rollers will start rotating. The machine operator will then simply have to properly align the rebar of choice and guide the rebar as it is inserted in between the rollers for the spiral bending. The machine operator will have to be mindful of the rollers and will have to carefully observe the rebars as it is being spirally being bent to avoid any unwanted injuries. The spiral bar bender has been designed for the comfort and safety of its valued operators so the machine operators simply have to be aware and sharp while operating the machine.

- The diameter of spirally bent rebar ranges from 130mm to 2,500mm. This allows the spiral bar bender to provide spirally bent rebars from a variety of diameters that are suitable for different civil engineering requirements. As mentioned above, the spiral rebar bender can be used for a variety of requirements in civil construction projects like bridge construction, subway work, and also for land base pilling work.

- The spiral bar bender is equipped with a 3 horse power motor that gives the machine a powerful bending capability. The machine's powerful bending performance can spirally bend up to 25mm. It will only take 12 seconds to bend a 32mm to 360°. The machine can efficiently bend rebars in the construction site as it is a heavy duty machine built to withstand hard work.

- Even though the machine is a heavy duty machine, it is extremely easy and simple to use. The spiral rebar bending machine was designed with the highest quality parts with an extremely simple machine operation process. CNB Machinery and Steel Corporation adhered to the feedback and comments of the machine operator's experience and continuously makes improvements in the machine and services.

- The spiral rebar bender is a triple phased machine. Make sure to properly phase the machines before proceeding with the bending of rebars in order to prevent any electrical damage that may not only halt the machine but may also hurt the machine operator.

- Although the machine is built with high quality parts, improper handling of the machine will lead to machine damage and malfunction. The interior electric motor must not be exposed to rain as this will cause the motor to be damaged which will halt the machine from working. This in return will cause delay in the production of spirally bent rebars. Moreover, this may also injure the machine operator in the process. CNB Machinery and Steel Corporation greatly values the safety of the machine operators and thus we highly recommend the machine operators to follow the instructions found in the machine manual as well as the demo of machines by our technicians upon delivery.

More videos of our 16mm Spiral Rebar Bender : TYR-HD25B

16mm Rebar Bender making spiral rebars

FAQs about our 16mm spiral rebar bending machine: TYR-HD25B

1. When do you recommend we use the TYR-HD25B?

When it comes to civil projects that are huge in scale like bridge construction, subway work and other land base filling projects, not only are electric rebar cutters and rebar benders used, but a spiral bender is also essential as well. Spirally bent deformed bars (rebars) will be reinforced with the help with the rebars spirally bent using a spiral bender. We highly recommend our TYR-HD25B spiral rebar bender as it can spirally bend 10mm to 36mm rebars.

2. What is the maximum number of rebars that the TYR-HD25B spiral bender can bend at once?

Our TYR-HD25B spiral rebar bender can bend one rebar at once whether it be 10mm or 16mm. That is the nature of spiral rebar benders as attempting to bend more than 1 rebar, no matter what the capacity of the rebar will tangle the rebars. Once again, only 1 piece of rebar is allowed to be bent using the spiral bar bender.

3. What is the maximum radius that the spiral bar bender can bend rebars?

The maximum bending radius of our spiral rebar bending machine is 360°.

4. Do you have spare parts ready on hand in your warehouse?

Yes. As the exclusive distributor of TAEYEON B&C rebar benders and rebar cutters here in the Philippines for over a decade, we have the privilege and responsibility of providing unrivaled after sales service to our clients. You may inquire using the contact us page here in the website, email us at [email protected] or simply call us in our mobile number or landline.

For any other questions, feel free to contact our sales team! When it comes to your rebar bender and rebar cutter requirements, the answer is CNB Machinery and Steel Corporation!

Reviews

There are no reviews yet.