Do we offer single phase to three phase conversion for our rebar bender and rebar cutters? Our clients would sometimes ask us that question. CNB Machinery and Steel Corporation has 7 semi-automatic machines. Out of the 7, 4 are electric rebar benders and 3 are electric rebar cutters. Among the 4 electric rebar benders, 2 models are single phased and 2 models are three phased. Our single phased bar benders are the TYB-D26 (25mm capacity bar bender) and TYB-D35 (32mm capacity bar bender). Among the 3 are electric rebar cutters, 2 models are single phased and 1 model is three phased.

What single phase machine can be converted to three phase?

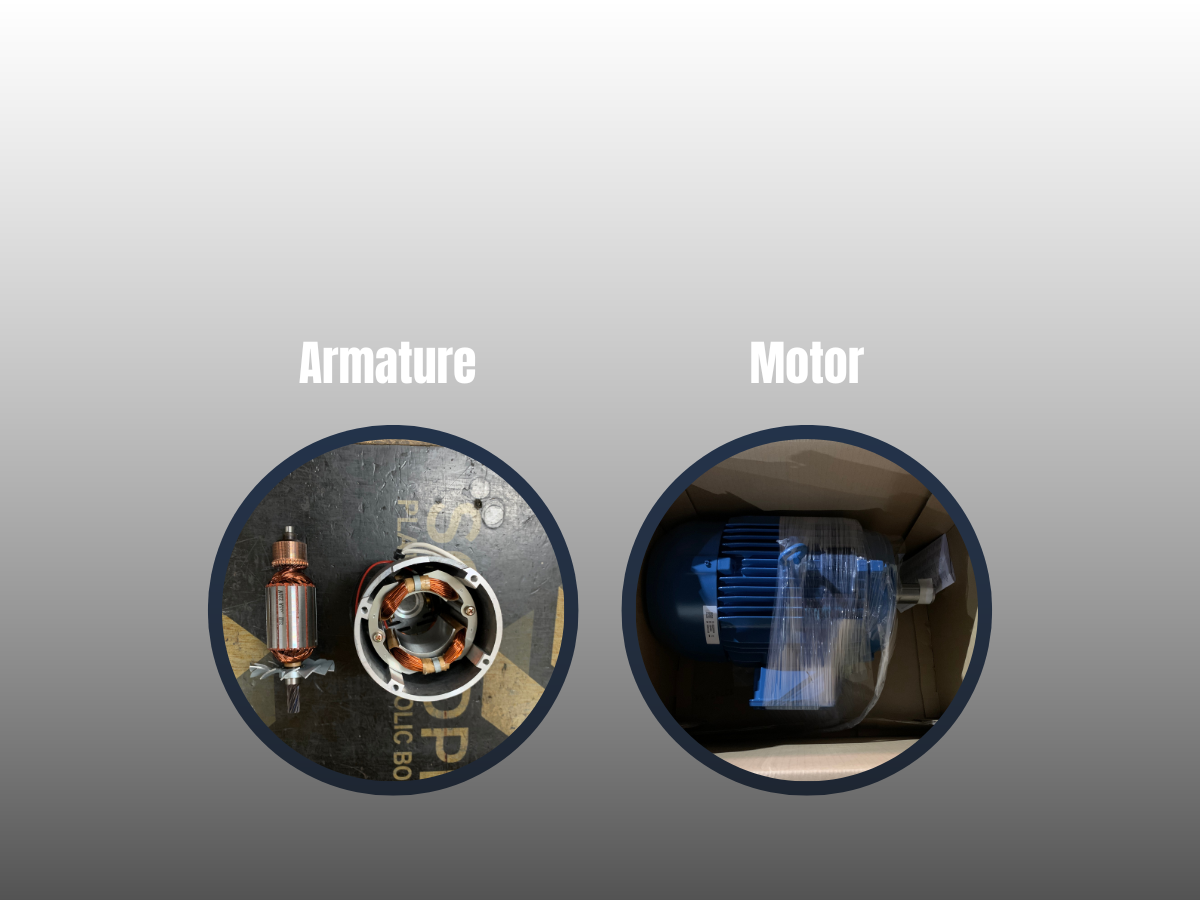

After more than a decade of experience in the field, our technicians have concluded that it will be safe to convert our TYC-D35 (32mm rebar cutter) to three phase. Single phase to three phase conversion is only possible with our TYC-D35. The other single phase machines cannot be converted into a three phase because they are run by an armature. On the other hand, our TYC-D35 although single phase is run with an electric motor which can be converted into three phase.

Can we convert our three phase machines into single phase?

Some of our clients have requested to convert their three phase machines into single phase. We have offered the conversion service to our clients. However, our technicians have concluded that it would be best for us not to offer conversion services as the converted machines were not stable, and often would have power fluctuations. Our three phase machines would require power and rotations that are needed to start the machine right away. However, if we would convert the machine into a single phase, the motor will lack the capacity to run the heavy duty machine.

What then is the recommendation?

With that being said, we highly recommend our clients to carefully consult with our sales team and follow the recommendations that our sales team would give. Our team provides transparent consultation that would recommend the machine that will fit the client’s requirements for their project. If the client’s project requires heavy duty machines that commands long work hours while handling rebar diameters that are 36mm and above, our sales team will recommend the heavy duty three phased rebar bender and rebar cutters.

If the requirement of our client commands them to fabricate 10-32mm rebars, our sales team will recommend them to go for our machines like our TYB-D26, TYB-D35 for the rebar benders and our TYC-NHD25 and our TYC-D35 for the rebar cutters.

Moreover, before we deliver our clients’ machines, or before we would permit them to pick their machines up from our warehouse, we highly recommend them to make sure that the proper and correct power supply is ready in the project site. Majority of the reasons why the machines of our clients would be damaged is because the project site is not equipped with the power supply.

Single phased machines are more sensitive to power supply issues and will have direct hits on power supply issues which can lead the engine motors or armatures to be heavily damaged. This is why we would always ask our clients to prepare the project site with the correct power supply. If our clients would follow the guidelines, the rebar bender and rebar cutters they would purchase from us will last them a very long time.

Each of our machines has its benefits and advantages which may differ based on the requirements of our clients. Our rebar bender and rebar cutters have been designed to aid and help our clients with the rebar fabrication duties. As mentioned earlier, as long as our clients would follow the guidelines that have been set, their machines will not be facing any electrical issues that will give unnecessary damages to the machine.